Drills

for machining perfection

Guhring manufactures a various range of drills to support central Thailand industries such as automotive, aerospace and mining industries.

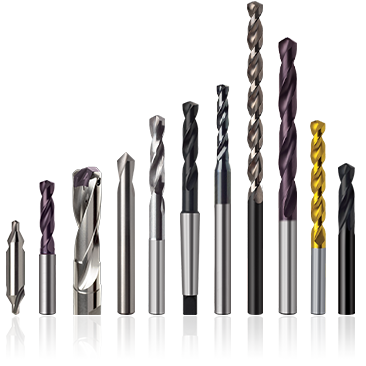

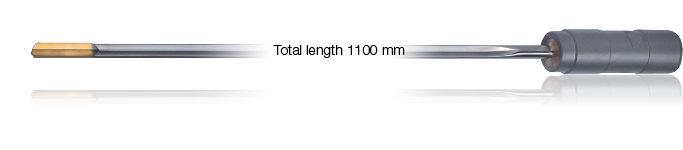

Guhring manufactures stub drills, jobber drills, twist drills, carbide drills, micro-precision drills, spade drills and deep hole drills. Spade drills are consist of drill body up to 10xD with interchangeable carbide inserts. Carbide spiral flute deep hole drills are up to 40xD available. Guhring also provides special carbide drills for specific industry needs.

Try Guhring high performance drill ranges now!