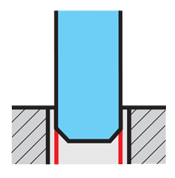

Hole too large

| Possible causes |

| Tool diameter too large |

| Cutting speed/feed rate too high |

| Concentricity error of machine spindle |

| Bevel lead of tool too short/uneven |

| Cutting edge build up |

| Lubricating agent unsuitable, holes too large due to lubrication |

| Axis shifting between tool and pre-drilled hole. Application of floating holders |